This document summarizes the key findings and recommendations from a National Algal Biofuels Technology Roadmap Workshop convened by the US Department of Energy in December 2008. The workshop brought together over 200 participants from industry, academia, national laboratories, and government agencies to identify technical barriers preventing the economical production of algal biofuels at commercial scale. The document outlines 10 areas that require further research and development to overcome these barriers, including algal biology, cultivation, downstream processing, extraction, conversion technologies, co-products, distribution and utilization, resources and siting, standards and regulations. The overall goal is to provide a comprehensive roadmap to guide future research needed before algal biofuels can be commercially viable.

![1457 Roessler PG (1988) Effects of Silicon Deficiency on Lipid-Composition and Metabolism

1458 in the Diatom Cyclotella-Cryptica. J. Phycol. 24:394-400

1459 Rolland F, Winderickx J, Thevelein JM (2001) Glucose-sensing mechanisms in

1460 eukaryotic cells. Trends Biochem.Sci. 26:310-317

1461 The Ecology of Algae by Round, F.E (1981) London: Cambridge University Press

1462 Ruuska SA, Girke T, Benning C et al., (2002) Contrapuntal networks of gene expression

1463 during Arabidopsis seed filling. Plant Cell 14:1191-1206

1464 Ryu JY, Song JY, Lee JM et al., (2004) Glucose-induced expression of carotenoid

1465 biosynthesis genes in the dark is mediated by cytosolic pH in the cyanobacterium

1466 Synechocystis sp. PCC 6803. J. Biol. Chem. 279:25320-25325

1467 Schwender J, Ohlrogge J, Shachar-Hill Y (2004) Understanding flux in plant metabolic

1468 networks. Curr. Opin. Plant Biol. 7:309-317

1469 Sheehan J, Dunahay T, Benemann J et al., (1998) US Department of Energy‘s Office of

1470 Fuels Development, July 1998. A Look Back at the US Department of Energy‘s

1471 Aquatic Species Program – Biodiesel from Algae, Close Out Report TP-580-24190.

1472 Golden, CO: National Renewable Energy Laboratory.

1473 Stahl U, Carlsson AS, Lenman M et al., (2004) Cloning and functional characterization

1474 of a Phospholipid: Diacylglycerol acyltransferase from Arabidopsis. Plant Physiol.

1475 135:1324-1335

1476 Vigeolas H, Mohlmann T, Martini N et al., (2004) Embryo-specific reduction of ADP-

1477 Glc pyrophosphorylase leads to an inhibition of starch synthesis and a delay in oil

1478 accumulation in developing seeds of oilseed rape. Plant Physiol. 136:2676-2686

1479 Zhekisheva M, Boussiba S, Khozin-Goldberg I et al., (2002) Accumulation of oleic acid

1480 in Haematococcus pluvialis (Chlorophyceae) under nitrogen starvation or high light is

1481 correlated with that of astaxanthin esters. J. Phycol. 38:325-331

1482 Zhu XG, de Sturler E, Long SP (2007) Optimizing the distribution of resources between

1483 enzymes of carbon metabolism can dramatically increase photosynthetic rate: A

1484 numerical simulation using an evolutionary algorithm. Plant Physiol. 145:513-526

1485 Zhu XG, Long SP, Ort DR (2008) What is the maximum efficiency with which

1486 photosynthesis can convert solar energy into biomass? Curr. Opin. Biotechnol.

1487 19:153-159

1488

1489 Biohydrogen: Direct Biophotolysis and Oxygen Sensitivity of the Hydrogen-

1490 Evolving Enzymes

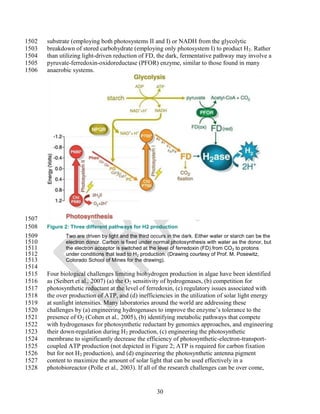

1491 Certain photosynthetic microbes, including algae and cyanobacteria, can produce H2 from

1492 the world‘s most plentiful resources in the following reactions: 2H2O + light energy →

1493 O2 + 4H+ + 4e- → O2 + 2H2. Two distinct light-driven H2-photoproduction pathways

1494 have been described in green algae, and there is evidence for a third, light-independent,

1495 fermentative H2 pathway coupled to starch degradation. All pathways have the reduction

1496 of ferredoxin (FD, Figure 2) in common as the primary electron-donor to a hydrogenase.

1497 Hydrogenases are enzymes that can reduce protons and release molecular H 2. The major

1498 types of enzymes contain either iron ([FeFe] hydrogenases, which generally are H2-

1499 evolving) or both nickel and iron ([NiFe] hydrogenases, which are generally H 2-uptake

1500 enzymes) in their active sites. More information about these O 2-sensitive enzymes are

1501 available (Ghirardi et al., 2007). The light-driven pathways can either use water as the

29](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-38-320.jpg)

![1529 H2-cost projections developed by the US Department of Energy suggest that biohydrogen

1530 could compete with gasoline at about $2.50 a kg (a gallon of gasoline contains the energy

1531 equivalent of about a kg of H2)

1532

1533 Recently, researchers have begun to re-examining the prospects for using cyanobacteria

1534 to produce H2. These studies are making use of bidirectional, [NiFe] hydrogenases that

1535 are found in some of these organisms rather than nitrogenases. While many of the same

1536 challenges identified in eukaryotic algae are also inherent in cyanobacteria, the

1537 advantages of working with these prokaryotic organisms are that they are more easily

1538 engineered than algae and have more O2-tolerant hydrogenases (Ghirardi et al., 2009). On

1539 the other hand, the [FeFe] hydrogenases, found in algae, are better catalysts than the

1540 [NiFe] hydrogenases found in cyanobacteria (citation).

1541

1542 Other future areas of investigation that researchers are staring to examine, include the

1543 application of biological knowledge of photosynthesis and hydrogenase

1544 structure/function to developing biohybrid systems (those employing biological and

1545 synthetic components) and, ultimately, totally artificial photosynthetic systems that

1546 mimic the fuel-producing processes of photosynthetic organisms.

1547

1548 Fermentative Hydrogen Production (Indirect Biophotolysis)

1549 Both algae and cyanobacteria carry out oxygenic photosynthesis. The former stores starch

1550 and the latter stores glycogen as the main carbon sink. To circumvent the inhibition of

1551 hydrogenase by O2, another option for H2 production is to take advantage of the

1552 fermentation pathways that exist in both microbes for H2 production at night, using the

1553 carbon reserves produced during the day. In cyanobacteria, fermentation is constitutive,

1554 accounting for their ability to adapt quickly to changing environmental conditions. All

1555 cyanobacteria examined thus far employ the Embden-Meyerhof-Parnas (EMP) pathway

1556 for degradation of glucose to pyruvate. From here several cyanobacteria were found to

1557 couple reductant to pyruvate-ferredoxin oxidoreductase, which reduces ferredoxin for

1558 subsequent H2 production via either nitrogenases or hydrogenases (Stal and Moezelaar,

1559 1997). This temporal separation of H2 production from photosynthesis has been

1560 demonstrated in the unicellular cyanobacteria Cyanothece sp. ATCC 51142 (Toepel et

1561 al., 2008) and Oscillatoria (Stal and Krumbein, 1987) using nitrogenase as the catalyst.

1562 Using hydrogenase as the catalyst, the unicellular non-N2-fixing cyanobacterium

1563 Gloeocapsa alpicola evolves H2 in the resulting from the fermentation of stored glycogen

1564 (Serebryakova et al., 1998). Similarly under non-N2 fixing condition, the hydrogenase

1565 from Cyanothece PCC 7822 produces H2 in the dark and also excretes typical

1566 fermentation by-products including acetate, formate, and CO2. (van der Oost et al. , 1989)

1567

1568 It is well established that dark fermentation suffers from low H 2 molar yield (less than 4

1569 moles of H2 per mol hexose) (Turner et al., 2008). This is due to the production of

1570 organic waste by-products described above along with ethanol. In order to fully realize

1571 the potential of H2 production via indirect biophotolysis, several challenges must be

1572 addressed: (a) improve photosynthetic efficiency to increase the yield of carbohydrate

1573 accumulation; (b) remove or down-regulate competing fermentative pathway thus

1574 directing more of the cellular flux toward H2 production; and (c) express multiple (both

31](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-40-320.jpg)

![1575 [FeFe] and [NiFe])hydrogenases in green algae and cyanobacteria so that electrons from

1576 both ferredoxin (Fd) and NAD(P)H can serve as electron donor to support H2 production.

1577

1578 References

1579

1580 Cohen, J., K. Kim, M. Posewitz, M.L. Ghirardi, K. Schulten, M. Seibert and P. King,

1581 ―Finding Gas Diffusion Pathways in Proteins: Application to O2 and H2 Transport in

1582 CpI [FeFe]-Hydrogenase and the Role of Packing Defects‖, Structure 13:1321-1329,

1583 2005.

1584 Ghirardi, M.L., A. Dubini, J. Yu and P.C. Maness, ―Photobiological Hydrogen-Producing

1585 Systems‖, Chemical Society Reviews 38: 52-61, 2009.

1586 Ghirardi, M.L., M.C. Posewitz, P.C. Maness, A. Dubini, J. Yu and M. Seibert,

1587 ―Hydrogenases and Hydrogen Photoproduction in Oxygenic Photosynthetic

1588 Organisms‖, Annual Review Plant Biology 58:71-91, 2007.

1589 Kosourov, S.N. and M. Seibert, ―Hydrogen Photoproduction by Nutrient-Deprived

1590 Chlamydomonas reinhardtii Cells Immobilized within Thin Alginate Films under

1591 Aerobic and Anaerobic Conditions‖, Biotechnology and Bioengineering 102:50-58,

1592 2009.

1593 Kruse, O., J. Rupprecht, K.P. Bader, S. Thomas-Hall, P.M. Schenk, G. Ginazzi and B.

1594 Hankamer, ―Improved Photobiological H2 Production in Engineered Green Algal

1595 Cells‖, Journal Biological Chemistry 280:34170-34177.

1596 Laurinavichene, T.V., S.N. Kosourov, M.L. Ghirardi, M. Seibert and A.A. Tsygankov,

1597 ―Prolongation of H2 Photoproduction by Immobilized, Sulfur-Limited

1598 Chlamydomonas reinhardtii Cultures‖, Journal Biotechnology 134:275-277, 2008.

1599 Melis, A., L. Zhang, M. Forestier, M.L. Ghirardi and M. Seibert, ―Sustained

1600 Photobiological Hydrogen Gas Production upon Reversible Inactivation of Oxygen

1601 Evolution in the Green Alga Chlamydomonas reinhardtii‖, Plant Physiology

1602 122:127-135, 2000.

1603 Polle, J.E.W., S. Kanakagiri and A. Melis, ―tla1, a DNA Insertional Transformant of the

1604 Green Alga Chlamydomonas reinhardtii with a Truncated Light-Harvesting

1605 Chlorophyll Antenna Size‖, Planta 217:49-59, 2003.

1606 Seibert, M., P. King, M.C. Posewitz, A. Melis, and M.L. Ghirardi "Photosynthetic Water-

1607 Splitting for Hydrogen Production," in Bioenergy (J. Wall, C. Harwood, and A.

1608 Demain, Eds.) ASM Press, Washington DC, pp. 273-291, 2008.

1609 Serebryakova, L.T., M. Sheremetieva, and A.A. Tsygankov, ―Reversible hydrogenase

1610 activity of Gloeocapsa alpicola in continuous culture‖, FEMS Microbiol. Lett.

1611 166:89-94, 1998.

1612 Stal, L.J., and W.E. Krumbein, ―Temporal separation of nitrogen fixation and

1613 photosynthesis in the filamentous non-heterocystous cyanobacterium Oscillatoria

1614 sp.‖, Arch Microbiol. 149:76-80, 1987.

1615 Stal, L.J., and R. Moezelaar,. ―Fermentation in cyanobacteria‖, FEMS Microbiol. Rev.

1616 21:179-211, 1997.

1617 Toepel, J., E. Welsh, T.S. Summerfield, H.B. Pakrasi, and L.A. Sherman, ―Differential

1618 transcriptional analysis of the cyanobacterium Cyanothece sp. strain ATCC 51142

1619 during light-dark and continuous-light growth‖, J. Bacteriol. 190:3904-3913, 2008.

32](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-41-320.jpg)

![3401 Conclusion

3402 Achieving significant petroleum displacement from biofuels using algal biomass requires

3403 an efficient and effective extraction/fractionation process that recovers lipids, proteins

3404 and carbohydrates from algal biomass, while preserving their potential for biofuels and

3405 other applications. There is wide gap between the existing technologies and an industrial-

3406 scale microalgal based biofuel process. There are large gaps in our knowledge needed to

3407 develop extraction/fractionation processes, such as cell wall composition, chemistry, and

3408 ultrastructure, the impact of high water content and chemistry on the extracted materials,

3409 and understanding the effect of cultivation and strain selection on the production of

3410 carbohydrates and lipids. Additionally, the need for demonstration facilities to provide

3411 standardized materials and to develop new tools and methods is critical to accelerate

3412 progress toward the goal for biofuel production from microalgae. Lastly, the development

3413 of algal-based biofuels can be accelerated by using many of the approaches, tools and

3414 governmental programs already established for cellulosic ethanol.

3415

3416 References

3417 Biomass as Feedstock for a Bioenergy and Bioproducts Industry: The Technical

3418 Feasibility of a Billion-Ton Annual Supply: April 2005 DOE and USDA publication

3419

3420 Bligh, E.G. and Dyer, W.J., A rapid method for total lipid extraction and purification.

3421 Canadian Journal of Biochemistry and Physiology, 1959. 37: p. 911 – 917

3422

3423 Fajardo, A.R., Cerdain, L.E., Medina, A.R., Fernandex, F.G.A., and Molina Grima, E.,

3424 Lipid extraction from the microalgae Phaeodactylum tricornutum. European Journal of

3425 Lipid Science and Technology, 2007. 109: p. 120 – 126

3426

3427 Hara, A. and Radin, N.S., Lipid extraction of tissues with a low-toxicity solvent.

3428 Analytical Biochemisry, 1978. 90: p. 420 – 426

3429

3430 Park, P. K., Kima, E. Y. and Chub, K. H. (2007). "Chemical disruption of yeast cells for

3431 the isolation of carotenoid pigments." 53(2): 148-152

3432

3433 [Cartens, M., Moina Grima, E., Robels Medina, A., Gimenez Gimenez, A. and Ibanez

3434 Gonzalez, J. (1996). "Eicosapentaenoic acid (20:5n-3) from the marine microalgae

3435 Phaeodactylum tricornutum." Journal of the American Oil Chemists‘ Society 73: 1025-

3436 1031]

3437

3438 [Nagle, N. and Lemke, P. (1990). "Production of methyl ester fuel from microalgae."

3439 Applied Biochemistry and Biotechnology 24/25: 355 – 361]

3440

3441 [Molina Grima, E., Robels Medina, A., Gimenez Gimenez, A., Sanchez, J.A., Garcia

3442 Camacho, F., and Garcia Sanchez, J.L., Comparison between extraction of lipids and

3443 fatty acids from microalgal biomass. Journal of the American Chemical Society, 1994.

3444 71(9): p. 955 - 959]

74](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-83-320.jpg)

![3445

3446 [Iverson, S.J., Lang, S.L.C., and Cooper, M.H., Comparison of the Bligh and Dyer and

3447 Folch Methods for Total Lipid Determination in a Broad Range of Marine Tissue. Lipids,

3448 2001. 36(11): p. 1283 - 1287.].

3449

3450 [Lewis, T., Nichols, P.D., and McMeekin, T.A., Evaluation of extraction methods for

3451 recovery of fatty acids from lipid-producing microheterotrophys. Journal of Microbial

3452 Methods, 2000. 43: p. 107 - 116.]

3453

3454 [Lepage, R. and Roy, C.C., Improved recovery of fatty acid through direct

3455 transesterification without prior extraction or purification. Journal of Lipid Research,

3456 1984. 25: p. 1391 - 1396.]

3457

3458 [Rodriguez-Ruiz, J., Belarbi, E.H., Sanchez, J.L.G., and Alonso, D.L., Rapid

3459 simultaneous lipid extraction and transesterification for fatty acid analysis. Biotechnology

3460 Techniques, 1998. 12(9): p. 689 - 691.]

3461

3462 Carvalho, A.P. and Malcata, F.X., Preparation of Fatty Acid Methyl Esters for Gas-

3463 Chromatographic Analysis of Marine Lipids: Insight Studies. Journal of Agricultural and

3464 Food Chemistry, 2005. 53: p. 5049 - 5059.]

3465

3466 [Herrero, M., Cifuentes, A., and Ibanez, E., Sub- and supercritical fluid extraction of

3467 functional ingredients from different natural sources: Plants, food-by-products, algae and

3468 microalgae. A review. Food Chemistry, 2006. 98: p. 136 – 148; Richter, B.E., Jones,

3469 B.A., Ezzell, J.L., Porter, N.L., Avdalovic, N., and Pohl, C., Accelerated solvent

3470 extraction: a technique for sample preparation. Analytical Chemistry, 1996. 68: p. 1033 -

3471 1039]

3472

3473 [Ayala, R. s. and Castro, L. (2001). "Continuous subcritical water extraction as a useful

3474 tool for isolation of edible essential oils." Food Chemistry 75: 109 – 113]

3475

3476 [Mok, W. S.-L. and Antal Jr., M. J. (1992). "Uncatalyzed solvolysis of whole biomass

3477 hemicellulose by hot compressed liquid water." Industrial & Engineering Chemistry

3478 Research 31(4): 1157 – 1161].

3479

3480 [Eikani, M. H., Golmohammad, F. and Rowshanzamir, S. (2007). "Subcritical water

3481 extraction of essential oils from coriander seeds (Coriandrum sativium L)." Journal of

3482 Food Engineering 80: 735 – 740]

3483

3484

3485 [Guclu-Ustundag, O., Balsevich, J. and Mazza, G. (2007). "Pressurized low polarity

3486 water extraction of sponins from cow cockle seed." Journal of Food Engineering 80: 619

3487 – 630]

3488

75](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-84-320.jpg)

![3489 [Richter, B. E., Jones, B. A., Ezzell, J. L., Porter, N. L., Avdalovic, N. and Pohl, C.

3490 (1996). "Accelerated solvent extraction: a technique for sample preparation." Analytical

3491 Chemistry 68: 1033 -1039]

3492

3493 [Denery, J. R., Dragull, K., Tang, C. S. and Li, Q. X. (2004). "Pressurized Fluid

3494 Extraction of carotenoids from Haematococcus pluvialis and Dunaliella salina and

3495 kavalactones from Piper methysticum." Analytica Chimica Acta 501 175 – 181]

3496

3497 [Schafer, K. (1998). "Accelerated solvent extraction of lipids for determining the fatty

3498 acid composition of biological material." Analytica Chimica Acta 358: 69 – 77]

3499

3500 [Dionex, C. (2007). "Accelerated solvent extraction techniques for in-line selective

3501 removal of interferences." Technical Note 210(LPN 1931): Sunnyvale, CA].

3502

3503 [Luque de Castro, M. D., Valcarcel, M. and Tena, M. T. (1994). Supercritical Fluid

3504 Extraction. Heidelberg, Springer Verlag]

3505

3506 [Luque de Castro, M. D., Jimenez-Carmona, M. M. and Fernandez-Perez, V. (1999).

3507 "Towards more rational techniques for the isolation of valuable essential oils from

3508 plants." Trends in Analytical Chemistry 18(11): 708 – 715].

3509

3510 [Chueng, P. C. K. (1999). "Temperature and pressure effects on supercritical carbon

3511 dioxide extraction of n-3 fatty acids from red seaweed." Food Chemistry 65: 399 – 403].

3512

3513 [Hejazi, M. A., de Lamarlie, C., Rocha, J. M. S., Vermue, M., Tramper, J. and Wijffels, R.

3514 H. (2002)

3515

3516 [Hejazi, M. A., de Lamarlie, C., Rocha, J. M. S., Vermue, M., Tramper, J. and Wijffels, R.

3517 H. (2002). "Selective extraction of carotenoids from the microalgae Dunaliella salina

3518 with retention of viability." Biotechnology and Bioengineering 79(1): 29 - 36: 29 – 36].

3519

3520 (Shahidi, F., (2006) Nutraceuticals and specialty lipids and their co-products CRS series

3521 Vol. 5. ,. Olaizola, M. Biomol Eng. 2003 Jul; 20 (4-6):459-66

3522

3523 Nathan Mosier a, Charles Wyman , Bruce Dale , Richard Elander ,Y.Y. Lee , Mark

3524 Holtzapple , Michael Ladisch Features of promising technologies for pretreatment of

3525 lignocellulosic biomass Biores. Tech. 96 (2005) 673–686).

76](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-85-320.jpg)

![4167 Guncheva, M.; Zhiryakova, D.; Radchenkova, N.; Kambourova, M. Acidolysis of

4168 tripalmitin with oleic acid catalyzed by a newly isolated thermostable lipase. Journal

4169 of the American Oil Chemists' Society (2008), 85(2), 129-132.

4170 Hallgren, Anders; Andersson, Lars A.; Bjerle, Ingemar. High temperature gasification of

4171 biomass in an atmospheric entrained flow reactor. Adv. Thermochem. Biomass

4172 Convers., [Ed. Rev. Pap. Int. Conf.], 3rd (1994), Meeting Date 1993, 338-49.

4173 Hanssen, Jon F.; Indergaard, Mentz; Oestgaard, Kjetill; Baevre, Olav Arne; Pedersen,

4174 Tor A.; Jensen, Arne. Anaerobic digestion of Laminaria spp. and Ascophyllum

4175 nodosum and application of end products. Biomass (1987), 14(1), 1-13.

4176 Hawash, S.; Kamal, N.; Zaher, F.; Kenawi, O.; El Diwani, G. Biodiesel fuel from

4177 Jatropha oil via non-catalytic supercritical methanol transesterification. Fuel (2009),

4178 88(3), 579-582.

4179 Hirano, Atsushi; Samejima, Yasutaka; Hon-Nami, Koyu; Kunito, Shunji; Hirayama,

4180 Shin; Ueda, Ryohei; Ogushi, Yasuyuki. CO2 fixation and ethanol production by

4181 fermentative microalgae. Outdoor cultivation in a 50-L tubular bioreactor and co-

4182 fermentation with propionate in dark. Making a Business from Biomass in Energy,

4183 Environment, Chemicals, Fibers and Materials, Proceedings of the Biomass

4184 Conference of the Americas, 3rd, Montreal, Aug. 24-29, 1997 (1997), 2, 1069-1076.

4185 Hirano, Atsushi; Ueda, Ryohei; Hirayama, Shin; Ogushi, Yasuyuki. CO 2 fixation and

4186 ethanol production with microalgal photosynthesis and intracellular anaerobic

4187 fermentation. Energy (Oxford) (1997), 22(2/3), 137-142.

4188 Hirayama, S.; Ueda, R.; Ogushi, Y.; Hirano, A.; Samejima, Y.; Hon-Nami, K.; Kunito, S.

4189 Ethanol production from CO2 by fermentative microalgae. Studies in Surface Science

4190 and Catalysis (1998), 114 (Advances in Chemical Conversions for Mitigating CO2),

4191 657-660.

4192 Hon-Nami, Koyu. A unique feature of hydrogen recovery in endogenous starch-to-

4193 alcohol fermentation of the marine microalga, Chlamydomonas perigranulata.

4194 Applied Biochemistry and Biotechnology (2006), 129-132, 808-828.

4195 Hossain, A. B. M. Sharif; Salleh, Aishah; Boyce, Amru Nasrulhaq; Chowdhury, Partha;

4196 Naqiuddin, Mohd. Biodiesel fuel production from algae as renewable energy.

4197 American Journal of Biochemistry and Biotechnology (2008), 4(3), 250-254.

4198 Kalva, Abhishek; Sivasankar, Thirugnanasambandam; Moholkar, Vijayanand S.

4199 Physical Mechanism of Ultrasound-Assisted Synthesis of Biodiesel. Industrial &

4200 Engineering Chemistry Research (2009), 48(1), 534-544.

4201 Lertsathapornsuk, V.; Pairintra, R.; Aryusuk, K.; Krisnangkura, K. Microwave assisted

4202 in continuous biodiesel production from waste frying palm oil and its performance in

4203 a 100 kW diesel generator. Fuel Processing Technology (2008), 89(12), 1330-

4204 1336.

4205 Liao, Hui-Fen; Tsai, Wei-Chuan; Chang, Shu-Wei; Shieh, Chwen-Jen. Application of

4206 solvent engineering to optimize lipase-catalyzed 1,3-diglyacylcerols by mixture

4207 response surface methodology. Biotechnology Letters (2003), 25(21), 1857-1861.

4208 Lopez-Hernandez, Arnoldo; Garcia, Hugo S.; Hill, Charles G., Jr. Lipase-catalyzed

4209 transesterification of medium-chain triacylglycerols and a fully hydrogenated soybean

4210 oil. Journal of Food Science (2005), 70(6), C365-C372.

4211 McNeff, Clayton V.; McNeff, Larry C.; Yan, Bingwen; Nowlan, Daniel T.; Rasmussen,

4212 Mark; Gyberg, Arlin E.; Krohn, Brian J.; Fedie, Ronald L.; Hoye, Thomas R. A

92](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-101-320.jpg)

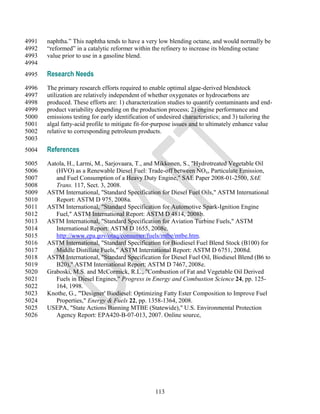

![4900 Utilization

4901 The last remaining hurdle to creating a marketable new fuel after it has been successfully

4902 delivered to the refueling location is that the fuel must meet regulatory and customer

4903 requirements. As mentioned in section 6, Algal Biofuel Conversion Technologies, such a

4904 fuel is said to be ―fit for purpose.‖ Many physical and chemical properties are important

4905 in determining whether a fuel is fit for purpose; some of these are energy density,

4906 oxidative and biological stability, lubricity, cold-weather performance, elastomer

4907 compatibility, corrosivity, emissions (regulated and unregulated), viscosity, distillation

4908 curve, ignition quality, flash point, low-temperature heat release, metal content,

4909 odor/taste thresholds, water tolerance, specific heat, latent heat, toxicity, environmental

4910 fate, and sulfur and phosphorus content. Petroleum refiners have shown remarkable

4911 flexibility in producing fit for purpose fuels from feedstocks ranging from light crude to

4912 heavy crude to oil shales to tar sands to gasified coal to chicken fat and are thus among

4913 the stakeholders in reducing the uncertainty about the suitability of algal lipids as a

4914 feedstock for fuel production..

4915

4916 Typically, compliance with specifications promulgated by organizations such as ASTM

4917 International ensures that a fuel is fit for purpose (ASTM, 2008a; ASTM, 2008b; and

4918 ASTM, 2008c). Failure of a fuel to comply with even one of the many allowable property

4919 ranges within the prevailing specification can lead to severe problems in the field. Some

4920 notable examples included: elastomer-compatibility issues that led to fuel-system leaks

4921 when blending of ethanol with gasoline was initiated; cold-weather performance

4922 problems that crippled fleets when blending biodiesel with diesel was initiated in

4923 Minnesota in the winter; and prohibiting or limiting the use of the oxygenated gasoline

4924 additive MTBE in 25 states because it has contaminated drinking-water supplies

4925 (USEPA, 2007). In addition to meeting fuel standard specifications, algal biofuels, as

4926 with all transportation fuels, must meet Environmental Protection Agency regulations on

4927 combustion engine emissions.

4928

4929 The Workshop discussions on utilization issues surfaced another guiding truth that it is

4930 unreasonable to expect new specifications to be developed for algal fuels in the near term

4931 (i.e., at least not until significant market penetration has occurred); hence, producers of

4932 algal fuels should strive to meet prevailing petroleum-fuel specifications. Nevertheless,

4933 researchers should be continually re-evaluating the conversion process to seek algae-

4934 derived compounds with improved performance, handling, and environmental

4935 characteristics relative to their petroleum-derived hydrocarbon counterparts. If significant

4936 benefits can be demonstrated, new specifications can be developed (e.g., [ASTM, 2008d;

4937 and ASTM, 2008e]).

4938

4939 The discussion below is divided into separate sections that deal with algal blendstocks to

4940 replace gasoline-boiling-range and middle-distillate-range petroleum products,

4941 respectively. These classifications were selected because the compounds comprising

4942 them are largely distinct and non-overlapping. Within each of these classifications,

4943 hydrocarbon compounds and oxygenated compounds are treated separately, since their

4944 production processes and in-use characteristics are generally different.

111](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-120-320.jpg)

![4945

4946 Algal Blendstocks to Replace Middle-Distillate Petroleum Products

4947 Petroleum ―middle distillates‖ are typically used to create diesel and jet fuels. The

4948 primary algae-derived blendstocks that are suitable for use in this product range are

4949 biodiesel (oxygenated molecules) and renewable diesel (hydrocarbon molecules). The

4950 known and anticipated end-use problem areas for each are briefly surveyed below.

4951

4952 Oxygenates: Biodiesel

4953 Biodiesel is defined as ―mono-alkyl esters of long chain fatty acids derived from

4954 vegetable oils or animal fats‖ (ASTM, 2008d). Biodiesel has been demonstrated to be a

4955 viable fuel for compression-ignition engines, both when used as a blend with petroleum-

4956 derived diesel and when used in its neat form (i.e., 100% esters) (Graboski, 1998). The

4957 primary end-use issues for plant-derived biodiesel are: lower oxidative stability than

4958 petroleum diesel, higher emissions of nitrogen oxides (NO x), and cold-weather

4959 performance problems (Knothe, 2008). The oxidative-stability and cold-weather

4960 performance issues of biodiesel preclude it from use as a jet fuel. The anticipated issues

4961 with algae-derived biodiesel are similar, with added potential difficulties including: 1)

4962 contamination of the esters with chlorophyll, metals, toxins, or catalyst poisons (e.g.,

4963 sulfur, phosphorus) from the algal biomass and/or growth medium; 2) undesired

4964 performance effects due to different chemical compositions; and 3) end-product

4965 variability.

4966

4967 Hydrocarbons: Renewable Diesel and Synthetic Paraffinic Kerosene

4968 The hydrocarbon analog to biodiesel is renewable diesel, which is a non-oxygenated,

4969 paraffinic fuel produced by hydrotreating bio-derived fats or oils in a refinery (e.g.,

4970 [Aatola, et al., 2008]). Algal lipids can be used to produce renewable diesel or synthetic

4971 paraffinic kerosene (SPK), a blendstock for jet fuel. These blendstocks do not have

4972 oxidative-stability problems as severe as those of biodiesel, and renewable diesel actually

4973 tends to decrease engine-out NOx emissions. Nevertheless, unless they are heavily

4974 isomerized (i.e., transformed from straight- to branched-chain paraffins), renewable

4975 diesel and SPK will have comparable cold-weather performance problems as those

4976 experienced with biodiesel. Also, as was the case with algal biodiesel, contaminants and

4977 end-product variability are concerns.

4978

4979 Algal Blendstocks for Alcohol and Gasoline-Range Petroleum Products

4980 While much of the attention paid to algae is focused on producing lipids and the

4981 subsequent conversion of the lipids to diesel-range blending components (discussed

4982 above), algae are already capable of producing alcohol (ethanol) directly, and there are

4983 several other potential gasoline-range products that could be produced by algae-based

4984 technology/biorefineries. Petroleum products in the alcohols and gasoline range provide

4985 the major volume of fuels used by transportation vehicles and small combustion engines

4986 in the United States. Ethanol or butanols are the most common biofuels currently being

4987 considered for use in gasoline, and these alcohols can be produced from fermentation of

4988 starches and other carbohydrates contained in algae. Additionally, the hydro-treating of

4989 bio-derived fats or oils in a refinery will typically yield a modest amount gasoline

4990 boiling-range hydrocarbon molecules. Refiners refer to this material as ―hydro-cracked

112](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-121-320.jpg)

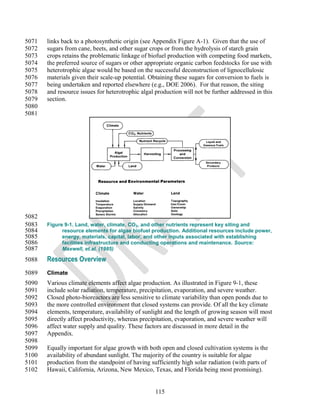

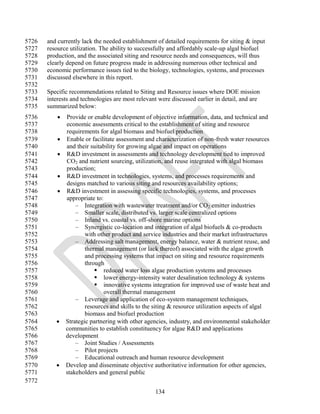

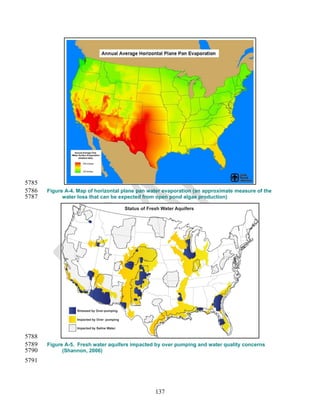

![5027

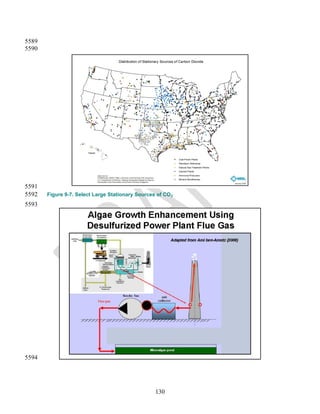

5028 9. Resources and Siting

5029 Introduction

5030 Successfully developing and scaling algal biofuels production, as with any biomass-based

5031 technology and industry, is highly dependent on siting and resources. Critical

5032 requirements, such as suitable land and climate, sustainable water resources, CO 2 and

5033 other nutrients must be appropriately aligned in terms of their geo-location,

5034 characteristics, availability, and affordability. Technical and economic success concurrent

5035 with minimal adverse environmental impact necessitates the matching of both, the siting

5036 and resource factors to the required growth conditions of the particular algae species

5037 being cultivated and the engineered growth system designs being developed and

5038 deployed.

5039

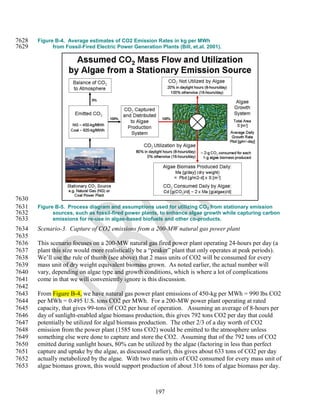

5040 Assessments of the resource requirements and availability for large-scale autotrophic

5041 algal cultivation were conducted during the Aquatic Species Program [e.g., Maxwell,

5042 et.al., (1985)], primarily in the Southwest region of the United States. Many of the

5043 findings of this and other earlier assessments still hold true today. Sufficient resources

5044 were identified by Maxewell, et.al. (1985) for the production of many billions of gallons

5045 of fuel, suggesting that algae have the potential to significantly impact U.S. petroleum

5046 consumption. However, the costs of these resources can vary widely depending upon

5047 such factors as land leveling requirements, depth of aquifers, distance from CO2 point

5048 sources, and others. Figure 9-1 provides a simple high-level illustration of the major

5049 resource and environmental parameters that pertain to the inputs of climate, water, and

5050 land. These parameters are of greatest importance to siting, design, production efficiency,

5051 and costs. For each parameter, a variety of conditions may be more or less cost-effective

5052 to siting and operation of algal biomass production.

5053

5054 In this section an overview of the critical resources for algal growth systems, specifically

5055 climate, water, carbon dioxide, and land, is presented. This is followed by in-depth

5056 discussion of algae biomass production relative to wastewater treatment and to CO2

5057 sequestration, both of which determine relevant siting opportunities for algal biofuel

5058 production. Analysis of current algal-based wastewater treatment techniques showing

5059 potential technical considerations for co-producing algal biofuel, such as recycling of

5060 wastewater is included. Similarly, the challenges associated with algae production from

5061 CO2 emitters are outlined.

5062

5063 Finally, the focus of this section is on siting and resource issues associated with algae

5064 biomass production based on autotrophic growth using energy from sunlight and the need

5065 for inorganic carbon and other key nutrients. It should be noted that heterotrophic algae

5066 that do not require light energy can be cultivated in waste treatment facilities or in closed

5067 industrial bioreactors in many locations throughout the country, and thus for the use of

5068 algae in this approach, an entirely different set of siting and resource criteria come into

5069 play. However, the affordable scale-up and successful commercial expansion via

5070 heterotrophic algae still requires an organic carbon feedstock – sugars - that ultimately

114](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-123-320.jpg)

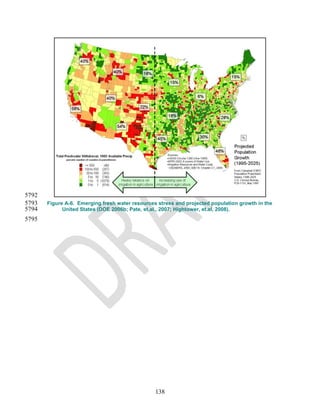

![5205 resources supply and management in the future (USGS 2009). Integrating algae

5206 production with wastewater treatment, discussed later in this section, leverages water that

5207 is potentially available.

5208

5209 The unique ability of many species of algae to grow in non-fresh water over a range of

5210 salinities means that, in addition to coastal and possible off-shore areas, other inland parts

5211 of the country can be targeted for algae production where brackish or saline groundwater

5212 supplies may be both ample and unused or underutilized. Data on brackish and saline

5213 groundwater resources is very outdated. An improved knowledge base is needed to better

5214 define the spatial distribution, depth, quantity, physical and chemical characteristics, and

5215 sustainable withdrawal rates for these non-fresh ground water resources, and to predict

5216 the effects of its extraction on the environment (Alley 2003). Saline groundwater

5217 resources, particularly deeper aquifers that are largely unregulated by state engineers and

5218 water authorities, are also increasingly being looked at as a source of water for treatment

5219 and use to meet growing needs for other industrial, commercial, and residential

5220 development in water sparse regions of the country, such as high population growth areas

5221 of the Southwest (Clark 2009).

5222

5223 Depth to groundwater is pertinent to the economics of resource development. Along with

5224 geological data, depth information determines the cost of drilling and operating

5225 (including energy input requirements for pumping) a well in a given location [Maxwell et

5226 al. (1985)]. Locations closer to the surface would provide a cost effective way for algae

5227 production. The locations and depths of saline aquifers in the United States is based on

5228 data from 1965, the last time this sort of survey was taken, therefore newer and more up-

5229 to-date information needs to be collected to improve our understanding of this resource in

5230 support of more detailed algae siting analyses. Produced water from petroleum, natural

5231 gas, and coal bed methane wells is an additional underutilized water resource that can

5232 range in quality from nearly fresh to hyper-saline.

5233

5234 Location, depth, potential yield, recharge rate, sustainability of supply, and quality

5235 (chemical components and characteristics) are critical in assessing non-fresh groundwater

5236 aquifer resource availability and suitability for algae production. Some of this

5237 information is available for major aquifers. However, if these aquifers are spread over

5238 large geographic areas, detailed analysis is difficult. Data on small, local aquifers may be

5239 available through state agencies and private engineering companies, but a significant

5240 effort would be required to identify, collect, and analyze this information.

5241

5242 Water use and consumption for algae-based biofuels will clearly be dependent on the

5243 type of growth systems used (open vs. closed vs. combination) and site-specific details of

5244 climate, solar insolation, weather conditions (cloud cover, wind, humidity, etc.). Another

5245 complicating factor will be the degree of salinity of the water used for cultivation.

5246

5247 Beyond evaporative water loss associated with algae cultivation (See Appendix), which

5248 can be expected to be significantly reduced if closed or hybrid systems are used, it will

5249 also be important to consider water use for the overall value chain from algal cultivation

5250 through harvesting and post-processing into fuels and other products. Along the way,

119](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-128-320.jpg)

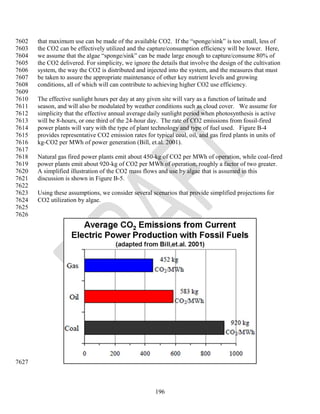

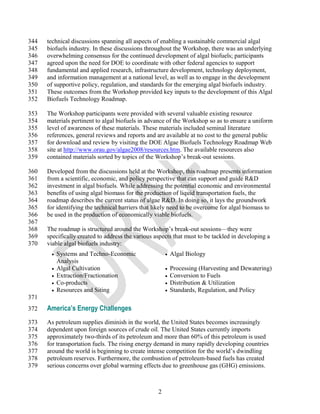

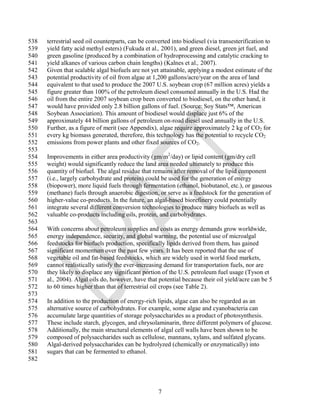

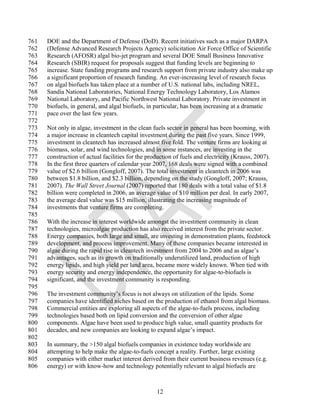

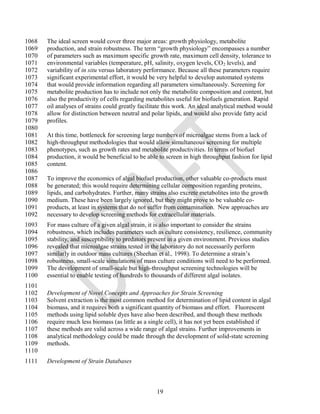

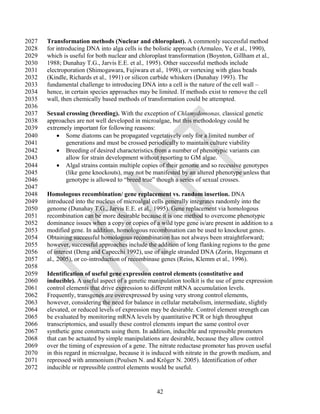

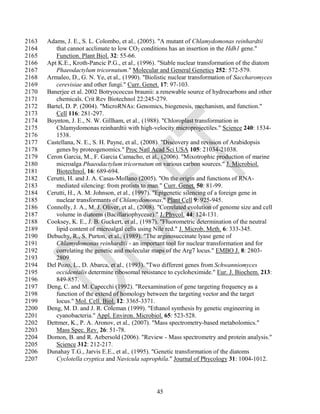

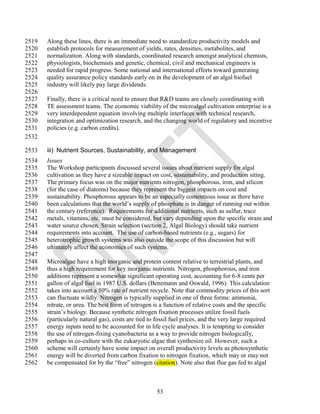

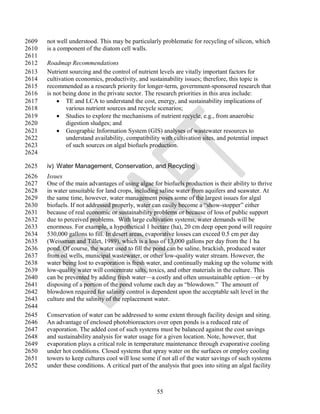

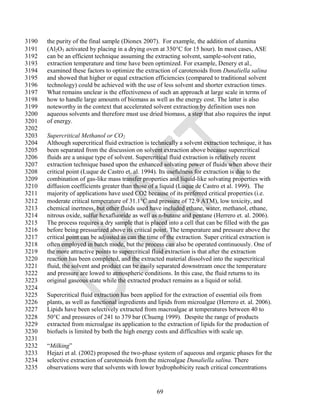

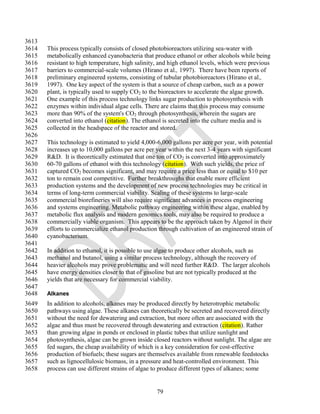

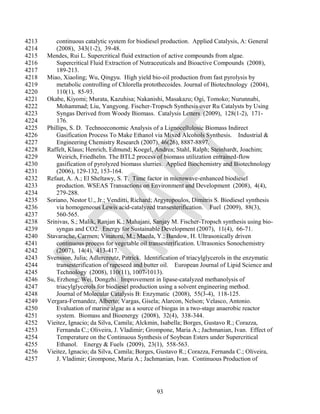

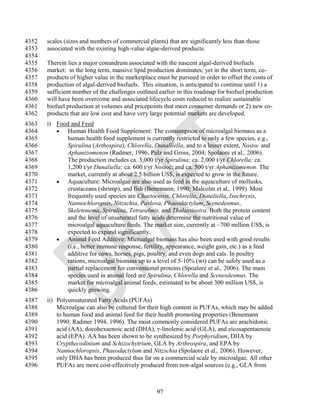

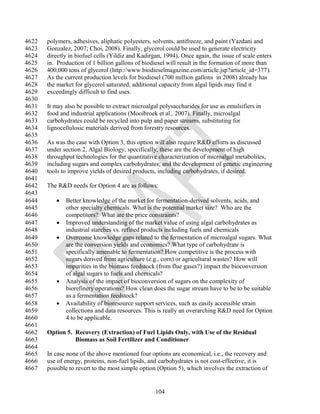

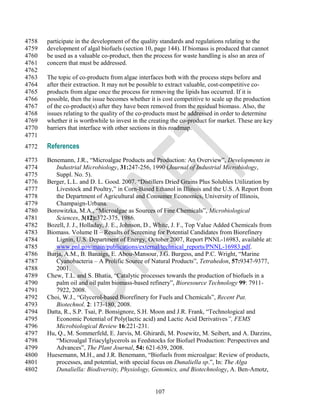

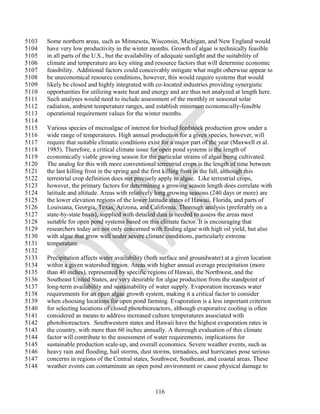

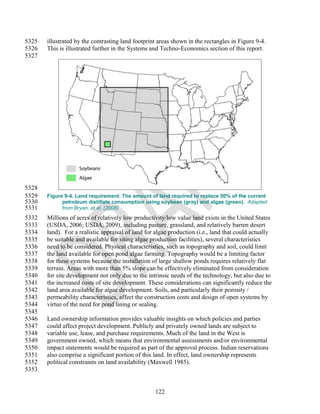

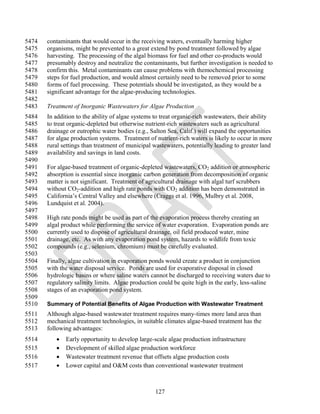

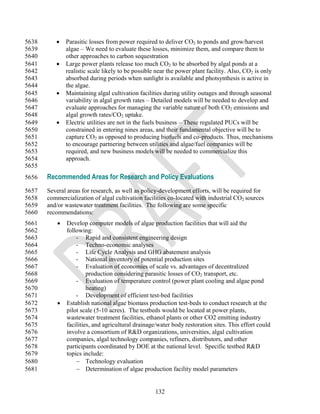

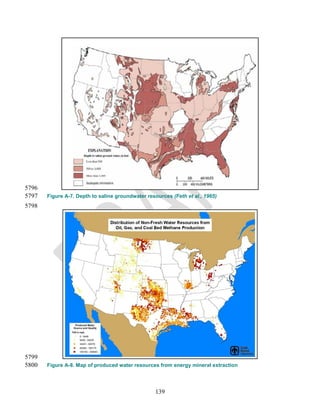

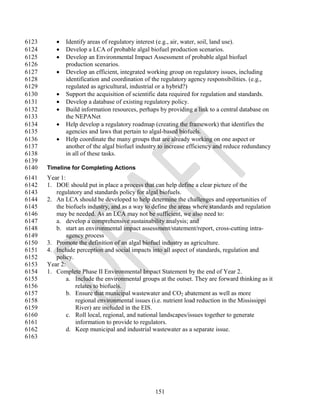

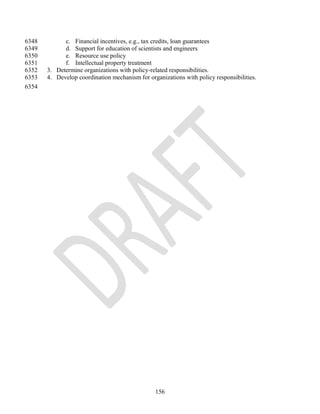

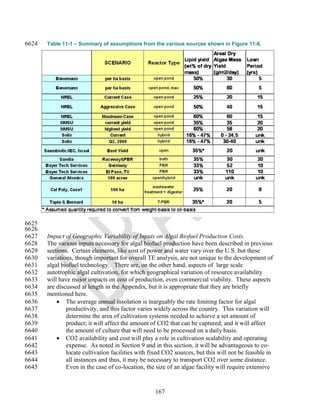

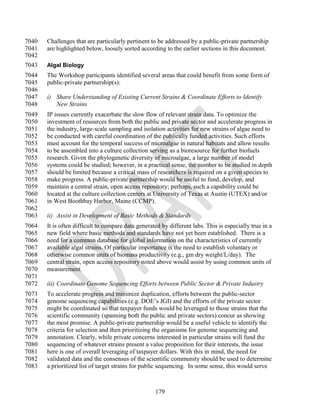

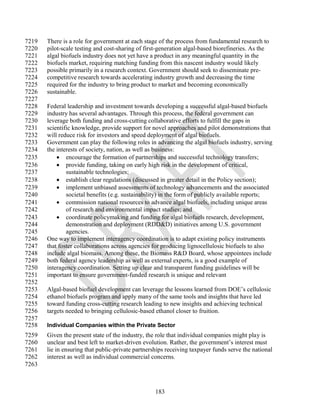

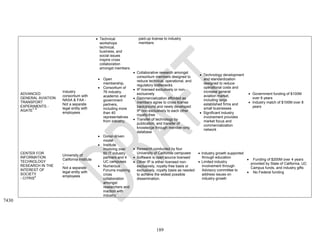

![Table 9-1. Major stationary CO2 sources in the United States [NATCARB

(2008)]

CO2 EMISSIONS Number of

CATEGORY Million Metric Ton/Year Sources

Ag Processing 6.3 140

Cement Plants 86.3 112

Electricity Generation 2,702.5 3,002

Ethanol Plants 41.3 163

Fertilizer 7.0 13

Industrial 141.9 665

Other 3.6 53

Petroleum and Natural

Gas Processing 90.2 475

Refineries/Chemical 196.9 173

Total 3,276.1 4,796

5296

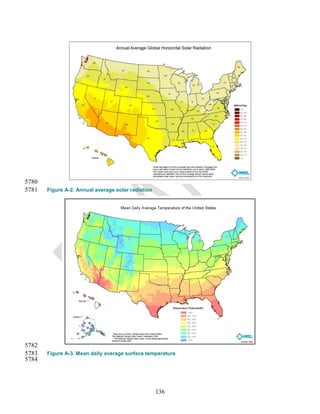

5297 Land

5298 Land availability is important for algae production because either open ponds or closed

5299 systems would require relatively large areas for implementation. Land availability is

5300 influenced by many physical, social, economic, legal, and political factors. Large surface

5301 area is required for algal production systems because of the limits on available sunlight

5302 energy and the photosynthesis-based conversion efficiency for algae biomass production.

5303 Despite having higher photosynthetic efficiencies than terrestrial plants, algae will be

5304 constrained by a practical upper limit on the amount of biomass growth that can be

5305 achieved per unit of illuminated surface. Also contributing to overall limitations of

5306 productivity per unit of surface area is the fact that algal cells nearest the illuminated

5307 surface absorb the light and shade their neighbors farther from the light source. Algal

5308 productivity is measured in terms of biomass produced per day per unit of available

5309 surface area (typically in units of grams/meter2/day or tons/acre/year of dry-weight-

5310 equivalent biomass). Even at levels of productivity that would stretch the limits of an

5311 aggressive R&D program (e.g., annual average of 60 g/m2/day with 50 % oil content on a

5312 dry weight basis), such systems will require 500 acres of land to produce 10 million

5313 gal/yr of oil feedstock, as discussed further in the Systems and Techno-Economics

5314 section of this report.

5315

5316 To put land requirements for biofuel production in perspective, the amount of cropland

5317 that would be required to replace half of the 64 billion gallons/year of petroleum

5318 currently used in the U.S. (which includes 44 billion gallons of petroleum diesel for

5319 transportation) would require unrealistically and unsustainably large cultivation areas

5320 using conventional oilseed crops. Soybeans, with an average oil yield of about 50-gal per

5321 acre, would require a land area equivalent to approximately 1 million miles 2 or roughly

5322 1.5 times the current amount of U.S. cropland (as illustrated by the larger rectangle in

5323 Figure 9-5). Based on the higher yields possible with algae, the equivalent volume of oil

5324 feedstock could potentially be produced with only 10,000 miles2 of land area, as

121](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-130-320.jpg)

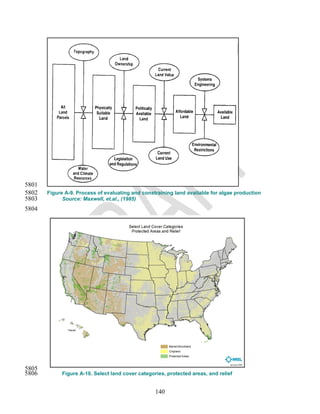

![5354 Land use and land value affect the land affordability. By reviewing historical economic

5355 analyses for lipid production to date, the cost of land is either not considered or relatively

5356 small compared to other capital cost, as discussed in the Systems and Techno-Economics

5357 section of this report. Land in high demand is therefore not desirable and not targeted for

5358 algae growth. Sensitive environmental or cultural land constraints will also reduce the

5359 overall land availability [Maxwell (1985)]. Examples of this type of constraint include

5360 parks, monuments, wildlife areas, archaeological sites, and historical monuments. On the

5361 other hand, some land cover characteristics could present excellent opportunities for

5362 algae farming. Land cover categories such as barren and scrubland cover a large portion

5363 of the West and may provide an area free from other food based agriculture where algae

5364 growth systems could be sited.

5365

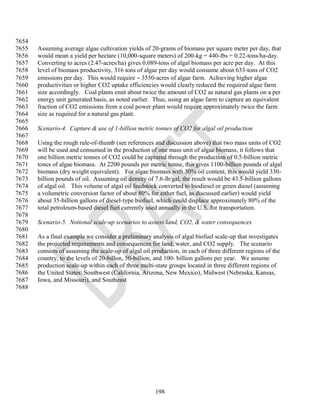

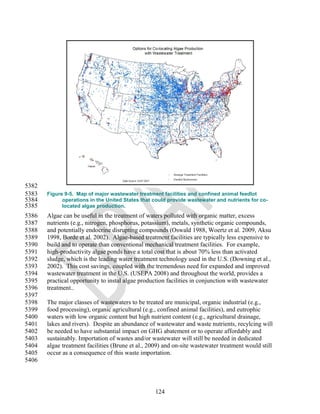

5366 Integration with Water Treatment Facilities, Power Utilities, Other Industries

5367 This subsection addresses the technical and economic challenges water and power

5368 utilities should consider with co-production of algae biomass. Both wastewater sources

5369 and industrial sources of CO2 that could be utilized for algae production are numerous

5370 and widely distributed in the U.S. Nevertheless, most barriers to algae production by

5371 utilities are common to all potential algae producers.

5372

5373 Water Treatment Applications

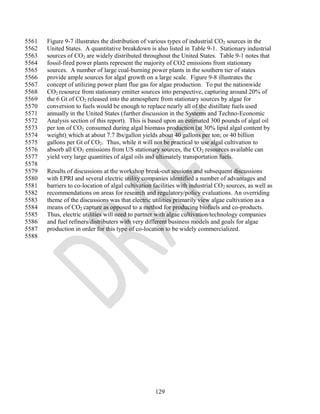

5374 Figure 9-5 shows national-level point sources for wastewater treatment facilities and

5375 feedlot operations. These represent the potential sites for algae operations. Two main

5376 types algae production facility are envisioned: dedicated facilities, with the main purpose

5377 of biomass production, and wastewater treatment facilities, which produce algal biomass

5378 as a consequence of the wastewater treatment. A subset of wastewater treatment facilities

5379 is evaporation facilities, which are used to dispose of wastewater or brines. The roles of

5380 these facility types in the development of an algae biofuels industry are discussed below.

5381

123](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-132-320.jpg)

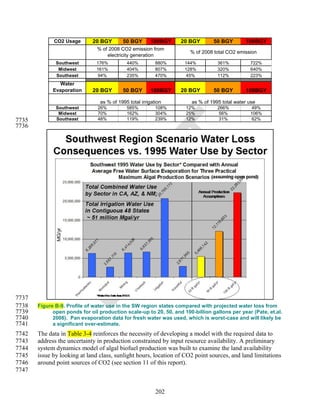

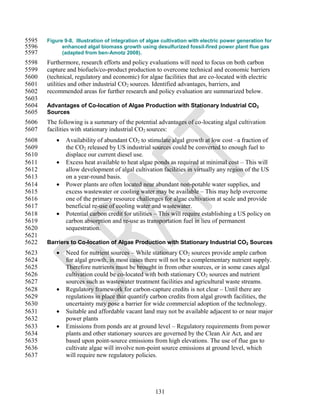

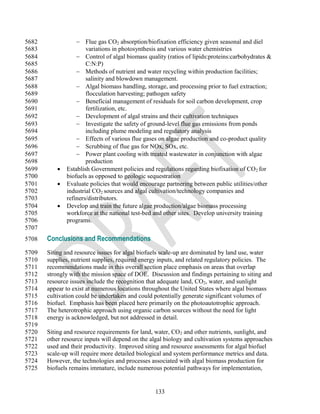

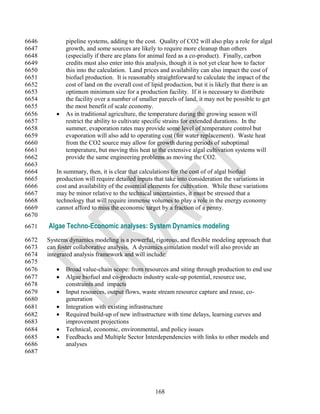

![7431 Appendix:

7432 Scenarios Illustrating Preliminary Consequence Assessment:

7433 Land, Water, and CO2 Demand for Algal Biofuels Scale-up

7434

7435 Establishing the Basis for Initial Algal Production Scale-up Assessments

7436

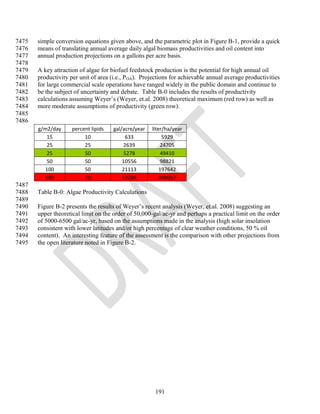

7437 Autotrophic algal productivity is typically measured in terms of dry weight biomass produced

7438 per day per unit of illuminated cultivation system (open pond, closed photobioreactor, or hybrid

7439 combination of open and closed systems) surface area. Typical units of measure include annual

7440 average grams/meter2-day, metric-tonnes/hectare-year, or tons/acre-year of dry-weight-

7441 equivalent biomass. Neutral lipid (oil) content in algae is typically measured in terms of

7442 percentage of dry weight biomass, resulting in oil productivity typically being measured in terms

7443 of metric-tonnes/hectare-year or gallons/acre-year.

7444

7445 Unit conversion factors useful for translation among the various units of measure can be found at

7446 the end of this Appendix.

7447

7448 The high energy density neutral lipid oils of immediate interest as biofuel feedstock from algae,

7449 as well as from other more conventional oil crops and waste oil sources (Tyson, et.al. 2004),

7450 consists largely of triacylglycerol (TAG). The volumetric density of TAG vegetable oils is ~

7451 0.92-grams/ml, which is equivalent to about 7.6-lbs/gal.

7452

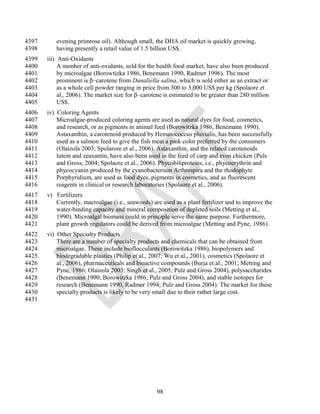

7453 Assuming an annual daily average algal biomass productivity of PBD [grams/m2-day] and an

7454 annual average oil content of L [%] produced over the period of a full 365-day year, the resulting

7455 annual average biomass production PBA [mt/ha-yr] and annual average oil production POA

7456 [gal/ac-yr] is be given by:

7457

7458 PBA [mt/ha-yr] = 3.65 [mt-m2-d/g-ha-yr] x PBD [gram/m2-day] (Eq B-1)

7459

7460 POA [gal/ac-yr] = 1.17 [gal-ha/mt-ac] x L [%] x PBA [mt/ha-yr] (Eq B-2)

7461

7462 POA [gal/ac-yr] = 1.17 x 3.65 x L [%] x PBD [g/m2-d]

7463

7464 = 4.27 [gal-m2-d/g-ac-yr] x L [%] x PBD [g/m2-d] (Eq B-3)

7465

7466 As an example, if we assume PBD = 30 g/m2-day and L= 25 % oil content, using the above

7467 equations gives (without specifying the units on the leading coefficient 4.27):

7468

7469 POA [gal/ac-yr] = 4.27 x 25 [%] x 30 [g/m2-day] ~ 3200 gal/ac-yr.

7470

7471 Figure B-1 provides a parametric mapping of annual average algal oil production, POA, in gal/ac-

7472 yr as a function of annual average daily biomass productivity, PBD, in g/m2-day and annual

7473 average neutral lipid content L in percent of dry weight algal biomass, as described in above

7474 equations. The example calculation above is also plotted in Figure B-1 for illustration. The

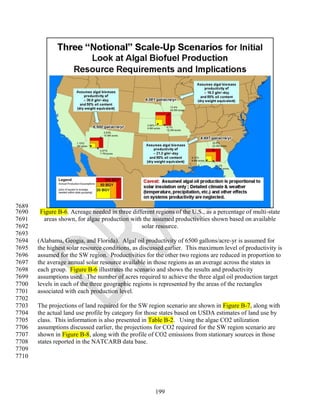

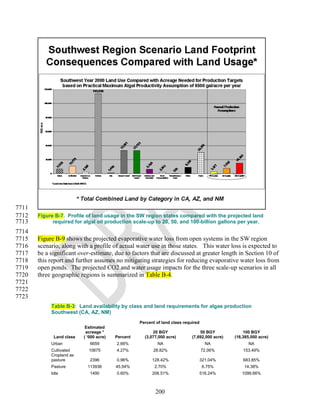

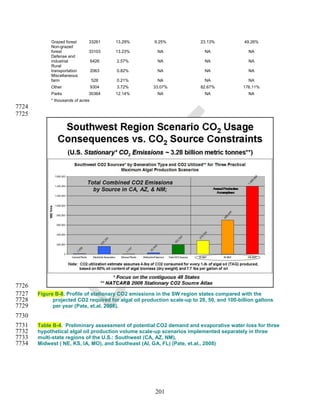

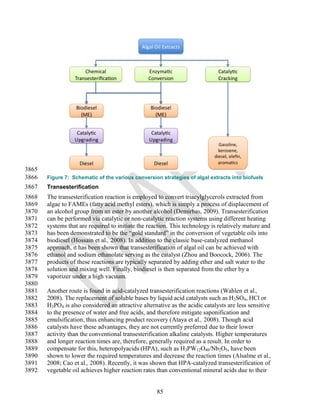

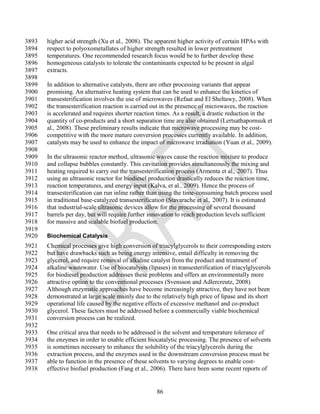

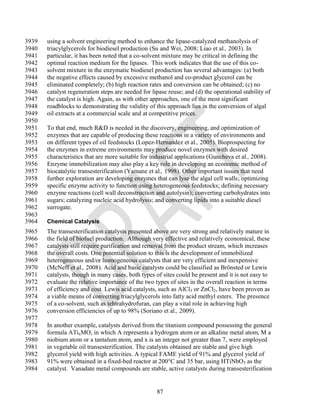

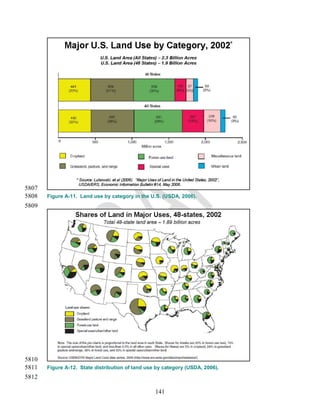

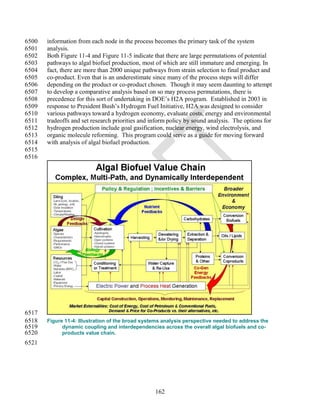

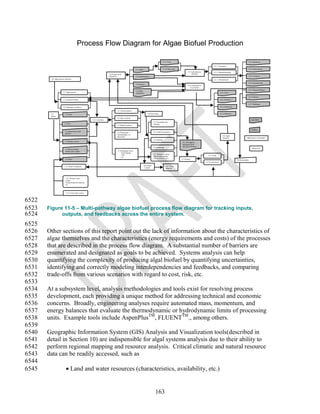

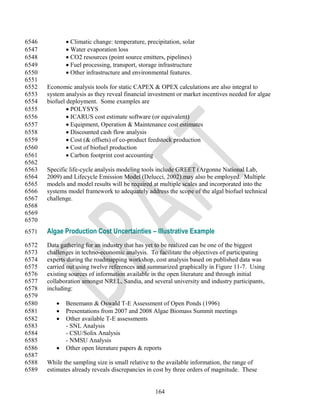

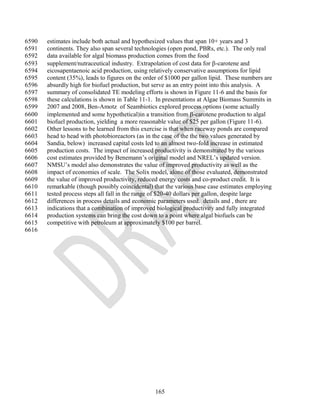

190](https://image.slidesharecdn.com/algalbiofuelsroadmap7-101006163553-phpapp01/85/Algal-biofuels-roadmap_7-199-320.jpg)